| Standard Casting Alloys Poured At Windmill Alloys | ||||||||||||||

| CAST ALLOY | SIMILAR WROUGHT DESIGNATION | SPECIFICATION | UNS No. | C | Cr | Ni | Mo | Cu | Fe | Cb | Other | Tensile | Yield | Elong. |

| CA6NM | 415 | ASTM-A743, A487 | J91540 | 0.06 | 11.5-14.0 | 3.5-4.5 | .4-1.0 | --- | --- | --- | --- | 110,000 | 80,000 | 15.00% |

| CA15 | 410 | ASTM-A217,A743 | J91150 | 0.15 | 11.5-14.0 | 1.0 | 0.50 | 0.50 | --- | --- | --- | 90,000 | 65,000 | 18.00% |

| CB7Cu-1 | 17-4 PH | ASTM-A747 | J92180 | 0.06 | 15.5-17.7 | 3.6-4.6 | --- | 2.5-3.2 | .15-.35 | --- | --- | 135,000 | 110,000 | 9.00% |

| AMS-5398C | H1100 Condition | |||||||||||||

| CF3 | 304L | ASTM-A351 | J92500 | 0.03 | 17.0-21.0 | 8.0-12.0 | 0.50 | --- | --- | --- | Mn 1.50 | 70,000 | 30,000 | 35.00% |

| A743, A744 | ||||||||||||||

| CF3MN | 316LN | ASTM-A743,A351 | J92804 | 0.03 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | 1.0 | 20.00 | --- | N- 0.10-0.20 | 70,000 | 30,000 | 30.00% |

| CF3M | 316L | ASTM-A351 | J92800 | 0.03 | 17.0-21.0 | 9.0-13.0 | 2.0-3.0 | --- | --- | --- | --- | 70,000 | 30,000 | 30.00% |

| A743, A744 | ||||||||||||||

| CF8 | 304 | ASTM-A351 | J92600 | 0.08 | 18.0-21.0 | 8.0-11.0 | 0.50 | --- | --- | --- | Mn 1.50 | 70,000 | 30,000 | 35.00% |

| A743, A744 | ||||||||||||||

| CF8C | 347 | ASTM-A351 | J92710 | 0.08 | 18.0-21.0 | 9.0-12.0 | --- | --- | --- | 8xC-1.0 | --- | 70,000 | 30,000 | 30.00% |

| A743, A744 | ||||||||||||||

| CF8M | 316 | ASTM-A351 | J92900 | 0.08 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | --- | --- | --- | Mn 1.50 | 70,000 | 30,000 | 30.00% |

| A743, A744 | ||||||||||||||

| CG3M | 317L | ASTM-A351 | --- | 0.03 | 18.0-21.0 | 9.0-13.0 | 3.0-4.0 | --- | --- | --- | --- | 75,000 | 35,000 | 25.00% |

| A743 , A744 | ||||||||||||||

| CG8M | 317 | ASTM-A351 | J93000 | 0.08 | 18.0-21.0 | 9.0-13.0 | 3.0-4.0 | --- | --- | --- | --- | 75,000 | 35,000 | 25.00% |

| A743 , A744 | ||||||||||||||

| CN7M | Alloy 20 | ASTM-A351 | N08007 | 0.07 | 19.0-22.0 | 27.5-30.5 | 2.0-3.0 | 3.0-4.0 | --- | --- | --- | 62,000 | 25,000 | 35.00% |

| A743, A744 | ||||||||||||||

| CX2MW | Hastelloy C-22 | ASTM A494 | N26022 | 0.02 | 20.0-22.5 | BAL | 12.5-14.5 | --- | 2.0-6.0 | --- | W-2.5-3.5 | 80,000 | 45,000 | 30.00% |

| CW2M | Hastelloy C4C | ASTM-A494 | N26455 | 0.02 | 15.0-17.5 | BAL | 15.0-17.5 | --- | 2.00 | --- | --- | 72,000 | 40,000 | 20.00% |

| CW6M | HastelloyC Modified | ASTM-A494 | N30107 | 0.07 | 17.0-20.0 | BAL | 17.0-20.0 | --- | --- | --- | --- | 72,000 | 40,000 | 25.00% |

| CW6MC | Inconel 625 | ASTM-A494 | N26625 | 0.06 | 20.0-23.0 | BAL | 8.0-10.0 | --- | 5.00 | 3.15-4.5 | --- | 70,000 | 40,000 | 25.00% |

| MIL-C-24615 | ||||||||||||||

| CW12MW | Hastelloy C | ASTM-A494 | N30002 | 0.12 | 15.5-17.5 | BAL | 16.0-18.0 | --- | 4.5-7.5 | --- | W-3.75-5.25 | 72,000 | 40,000 | 4.00% |

| Hastelloy C-276 | Same as above except C-.02 | V-.20-.40 | ||||||||||||

| CY40 | Inconel 600 | ASTM-A494 | N06040 | 0.40 | 14.0-17.0 | BAL | --- | --- | 11.00 | --- | --- | 70,000 | 28,000 | 30.00% |

| CZ100 | Cast Nickel | ASTM-A494 | N02100 | 1.00 | 1.5 | 95.0 min. | --- | 1.25 | 3.00 | --- | --- | 50,000 | 18,000 | 10.00% |

| N7M | HastelloyB modified | ASTM-A494 | N30007 | 0.07 | 1.0 | BAL | 30.0-33.0 | --- | 3.00 | --- | --- | 76,000 | 40,000 | 20.00% |

| N12MV | Hastelloy B | ASTM-A494 | N30012 | 0.12 | 1.0 | BAL | 26.0-30.0 | --- | 4.0-6.0 | --- | --- | 76,000 | 40,000 | 6.00% |

| M35-1 | Monel 400 | ASTM-A494 | N24135 | 0.12 | --- | BAL | --- | 26.0-33.0 | 3.50 | 0.50 | --- | 65,000 | 25,000 | 25.00% |

| M35-2 | Monel | ASTM-A494 | N04020 | 0.35 | --- | BAL | --- | 26.0-33.0 | 3.50 | 0.50 | --- | 65,000 | 30,000 | 25.00% |

| M35-B | H-Monel | QQ-N-288 Comp B | N24030 | 0.30 | --- | BAL | --- | 27.0-33.0 | 2.50 | --- | Si 2.7-3.7 | 100,000 | 60,000 | 10.00% |

| M35-C | Monel | QQ-N-288 Comp C | N24025 | 0.20 | --- | BAL | --- | 27.0-31.0 | 2.50 | --- | Si 3.3-3.7 | 120,000 | 80,000 | 10.00% |

| M35-D | S-Monel | QQ-N-288 Comp D | N24025 | 0.25 | --- | BAL | --- | 27.0-31.0 | 2.50 | --- | Si 3.5-4.5 | --- | --- | --- |

| M30C | Weldable Monel | ASTM-A494 | N24130 | 0.30 | --- | BAL | --- | 26.0-33.0 | 3.50 | --- | Cb 1.0-3.0 | 65,000 | 32,500 | 25.00% |

| 954 | Aluminum-Bronze | ASTM-B148 | C95400 | --- | --- | 1.5 max | --- | 83.0 min | 3.0-5.0 | --- | Al 10.0-11.5 | 75,000 | 30,000 | 12.00% |

| 955 | Aluminum-Bronze | ASTM-B148 | C95500 | --- | --- | 3.0-5.5 | --- | 78.0 min | 3.0-5.0 | --- | Al 10.0-11.5 | 90,000 | 40,000 | 6.00% |

| 958 | Ni-Al-Brz | ASTM-B148 | C95800 | 0.15 | --- | 4.0-5.0 | --- | 78.0 Min | 3.0-4.5 | --- | Al 8.5-9.5 | 85,000 | 35,000 | 15.00% |

| Pb .03 max | ||||||||||||||

| 964 | 70-30 Copper-Nickel | ASTM-B369 | C96400 | 0.15 | --- | 28.0-32.0 | --- | BAL | .25-1.5 | --- | Mn 1.5 max | 60,000 | 32,000 | 20.00% |

| CD4MCu | Duplex Grade 1A | ASTM-A351 | J93370 | 0.04 | 24.5-26.5 | 4.75-6.0 | 1.75-2.25 | 2.75-3.25 | BAL | --- | N 0.10-0.25 | 100,000 | 70,000 | 16.00% |

| 1B | A743 , A744 | |||||||||||||

| CE8MN | Duplex Grade 2A | ASTM-A890 | J93345 | 0.08 | 22.5-25.5 | 8.0-11.0 | 3.00-4.50 | --- | BAL | --- | N 0.10-0.30 | 95,000 | 65,000 | 25.00% |

| CD6MN | Duplex Grade 3A | ASTM-A890 | J93371 | 0.06 | 24.0-27.0 | 4.0-6.0 | 1.75-2.50 | --- | BAL | --- | N-0.15-0.25 | 95,000 | 65,000 | 25.00% |

| CD3MN | Duplex Grade 4A | ASTM-A890 | J92205 | 0.03 | 21.0-23.5 | 4.5-6.5 | 2.5-3.5 | 1.00 max | BAL | --- | N 0.10-0.30 | 90,000 | 60,000 | 25.00% |

| CE3MN | Duplex Grade 5A | ASTM-A890 | J93404 | 0.03 | 24.0-26.0 | 6.0-8.0 | 4.0-5.0 | --- | BAL | --- | N 0.10-0.03 | 100,000 | 75,000 | 18.00% |

| CD3MWCuN | Grade 6A Zeron100 | ASTM-A890 | J93380 | 0.03 | 24.0-26.0 | 6.5-8.5 | 3.0-4.0 | 0.5-1.0 | BAL | --- | N 0.02-0.03 | 100,000 | 65,000 | 25.00% |

| W 0.5-1.0 | ||||||||||||||

| CN2MCuN | 904L | ASTM-A351 | N08904 | 0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 1.0-2.0 | BAL | --- | Mn 2.0 max | 65,000 | 28,000 | 35.00% |

| CK3MCuN | Avesta 254-SMO | ASTM-A351 | S31254 | 0.025 | 19.5-20.5 | 17.5-19.5 | 6.00-7.00 | 0.50-1.00 | BAL | --- | Mn 1.20 | 80,000 | 38,000 | 35.00% |

| A-743, A-744 | ||||||||||||||

| CN3MN | AL6XN | ASTM-A351 | N08367 | 0.025 | 20.0-22.0 | 23.5-25.5 | 6.0-7.0 | 0.75 | BAL | --- | Mn 2.00 | 80,000 | 38,000 | 35.00% |

| A743, A744 | ||||||||||||||

| HH | 309 (25-12) | ASTM-A297 | J93503 | 0.20-0.50 | 24.0-28.0 | 11.0-14.0 | 0.05 | 1.0 | BAL | --- | Mn 2.00 | 75,000 | 35,000 | 10.00% |

| HK | 310 (25-20) | ASTM-A297 | J94224 | 0.20-0.60 | 24.0-28.0 | 18.0-22.0 | 0.05 | 1.0 | BAL | --- | Mn 2.00 | 65,000 | 35,000 | 10.00% |

| HN | HI-35 | ASTM-A297 | J94213 | 0.20-0.50 | 19.0-23.0 | 23.0-27.0 | 0.05 | 1.0 | BAL | --- | Mn 2.00 | 63,000 | --- | 8.00% |

| HT | 330 (15-35) | ASTM-A297 | N08605 | 0.35-0.75 | 15.0-19.0 | 33.0-37.0 | 0.05 | 1.0 | BAL | --- | Mn 2.00 | 65,000 | --- | 4.00% |

| HU | (19-39) | ASTM-A297 | N08004 | 0.35-0.75 | 17.0-21.0 | 37.0-41.0 | 0.50 | 1.0 | BAL | --- | Mn 2.00 | 65,000 | --- | 4.00% |

| HX | ACI HX | ASTM-A297 | N06006 | 0.35-0.75 | 15.0-19.0 | 64.0-68.0 | 0.05 | 1.0 | BAL | --- | Mn 2.00 | 60,000 | --- | --- |

| WCA | Carbon Steel | ASTM-A216 | J02502 | 0.25 | 0.50 | 0.50 | 0.20 | 0.30 | BAL | --- | Si 0.60 | 60-85,000 | 30,000 | 24.00% |

| WCB | Carbon Steel | ASTM-A216 | J03002 | 0.30 | 0.50 | 0.50 | 0.20 | 0.30 | BAL | --- | Si 0.60 | 70-95,000 | 36,000 | 22.00% |

| WCC | Carbon Steel | ASTM-A216 | JO2503 | 0.25 | 0.50 | 0.50 | 0.20 | 0.30 | BAL | --- | Si 0.60 | 70-95,000 | 40,000 | 22.00% |

| LCB | Carbon Steel | ASTM-A352 | J03003 | 0.30 | 0.50 | 0.50 | 0.20 | 0.30 | BAL | --- | Si 0.06 | 65,000 | 35,000 | 24.00% |

| LCC | Carbon Steel | ASTM-A352 | J02505 | 0.25 | 0.50 | 0.50 | 0.20 | 0.30 | BAL | --- | Si 0.60 | 70,000 | 40,000 | 22.00% |

| HC250 | 25% Chrome Iron | ASTM A532 Cl 3A | F45009 | 2.0-3.3 | 23.0-30.0 | 2.50 | 3.00 | 1.20 | BAL | --- | Si 1.50 | --- | --- | --- |

| 1. 254SMO is a registered trademark of Avesta AB. Wollaston Alloys is licensed to make 254SMO. | ||||||||||||||

| 2. Alloy 20 is a registered trademark of Carpenter Technology Corporation. | ||||||||||||||

| 3. Hastelloy is a registered trademark of Haynes International. | ||||||||||||||

| 4. AL6XN is a registered trademark of Allegheny Ludlum Incorporated. | ||||||||||||||

| 5. Zeron 100 is a registered trademark of Weir International. | ||||||||||||||

| 6. "Similar Wrought Designation". Wrought alloys have chemistries, mechanical properties or corrosion properties that may be different than the cast alloy. Wrought names are given as a reference for commonly accepted equivalent materials. | ||||||||||||||

| NOTE: Virtually any alloy specification can be handled by our versatile melting equipment. Many unlisted alloys can be cast. | ||||||||||||||

| Chemistries are maximums unless ranges are given. Quotations gladly furnished on request. | ||||||||||||||

Special Alloy Steel Material Chemical Analysis

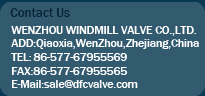

★Contact Now

If you have Special Alloy Steel Material Chemical Analysis any enquiry about quotation or cooperation, please feel free to email us at sale@dfcvalve.com or use the following enquiry form. WINDMILL sales representative will contact you within 24 hours. Thank you for your interest in our Special Alloy Steel Material Chemical Analysis products.