Aker new internal subsea tree cap can be installed and retrieved

by a remotely operated vehicle (ROV)

Aker Subsea recently introduced a new internal subsea tree cap that promises ease of installation at depths of 10,000 ft below the ocean surface. The cap, which can be installed and retrieved by a remotely operated vehicle (ROV), also promises more efficient installations at lower overall costs.

The Aker Subsea tree caps are designed for use on concentric bore, vertical subsea trees. The cap acts as a barrier to keep the subsea environment clean in the event of any leaks above the annulus and production swab valves.

In developing the tree cap, Aker Subsea met several design objectives, including:

The device does not present a snag hazard for future wellhead work, and should aid in damage control from dropped objects The device fits within and locks to the subsea tree spool body . The device is delivered ready for service and is manipulated subsea by the ROV, attributes which minimize rig activities and reduce the possibility of safety incidents . The device, when submerged, has relatively neutral buoyancy, thus minimizing the tasks that the ROV has to perform in its installation, operation, and subsequent retrieval Previous tree caps used in the industry generally required specific radial alignment of the cap to ensure proper insertion and secure placement in the subsea tree. Achieving a particular radial alignment is difficult when installing a tree cap with an ROV.

The design advantage of the Aker Subsea tree cap is that an ROV can install it into a subsea tree at any rotational orientation.

The tree cap has a primary and secondary locking mechanism actuated by hydraulic pressure to lock into the subsea tree and to set the metal seals. To prevent any damage to the metal seals during installation, the tree cap lands and locks into the tree by the primary locking mechanism prior to setting the metal seals.

The primary mechanism is activated when hydraulic pressure applied into the cavity moves a piston downward, which causes the upper set of locking dogs to move outward into the locking profile of the subsea tree. This selectively locks the tree cap into the tree.

The secondary lock mechanism consisting of a cam, rod, and spring method then sets and secures the metal seals, which are designed to isolate the annulus and production bores of the tree. Hydraulic pressure continues to force the seal carrier downward, which allows the cam and rod to move downward. This permits the lower sets of dogs to engage, thus securing the seal carrier with both metal seals into the designated position. The metal seals are tested and qualified to a working pressure of 15,000 psi and a temperature range of 0~250 °F.

The Aker Subsea tree cap includes a mechanism that indicates whether the metal seals have been accurately set within the seal bore of the tree, and the design also permits testing of the metal seals after installation. The tree cap is rated for deepwater applications up to 10,000 ft depth, with a working pressure of 10,000 psi and an operating system pressure of 3,000 psi.

To counter the problem of fluid becoming trapped between the cavity of the tree cap and the subsea tree, which would prevent the cap from properly landing into position, the design includes a flow path and ball valve which removes the water. The tree cap allows corrosion inhibitor to be injected into the cavity between the tree and cap and into the bores above the annulus and production valves.

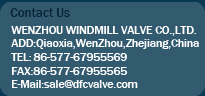

Aker Subsea